Client Stories

Thorough Quality Management and Various Other Actions to Establish Relationships of Trust with Customers

Keiichi Nishihara, Representative Director and President, NISHIHARA RIKOH Co., Ltd.

ABOUT THE COMPANY

NISHIHARA RIKOH Co., Ltd. has been doing business as a specialized plating manufacturer since its establishment in 1951. Now the company mainly plates semiconductor and electronic parts. The semiconductor-related business is subject to large economic fluctuations and has been facing various difficulties. This is the context in which the company has been working on ISO, TPM, and other quality management and productivity enhancement activities. They have also been working on PSE, which supports all processes from planning and development to trial manufacturing and mass production. What made the company work on such activities? Which direction is the company aiming for in the future? We interviewed Mr. Keiichi Nishihara, Representative Director and President.

Great Many Technologies Improved under the Influence of Business Conditions

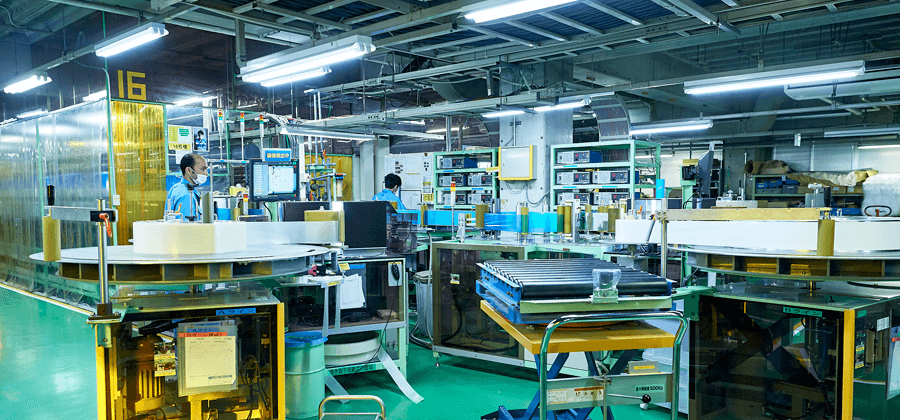

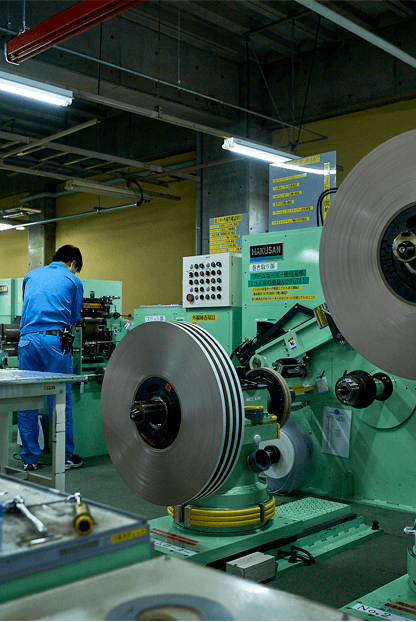

Integrated continuous plating line including necessary processes before and after plating

There are various plating manufacturers according to uses and specifications. Nishihara Ricoh excels at plating metal materials for semiconductor and electronic parts using a technology called continuous plating. Aluminum continuous plating is particularly attracting attention from many companies as a technology capable of making aluminum available as a current-carrying part by making use of the characteristics of its light weight and low cost. N-Sn is a high-performance tin plating technology featuring no thermal discoloring that the company developed independently, and they have a registered trademark for it. The company has been improving many characteristic technologies to survive despite the collapse of the IT bubble and the 2008 financial crisis.

Direct Communications by Engineers to Immediately Clarify Issues

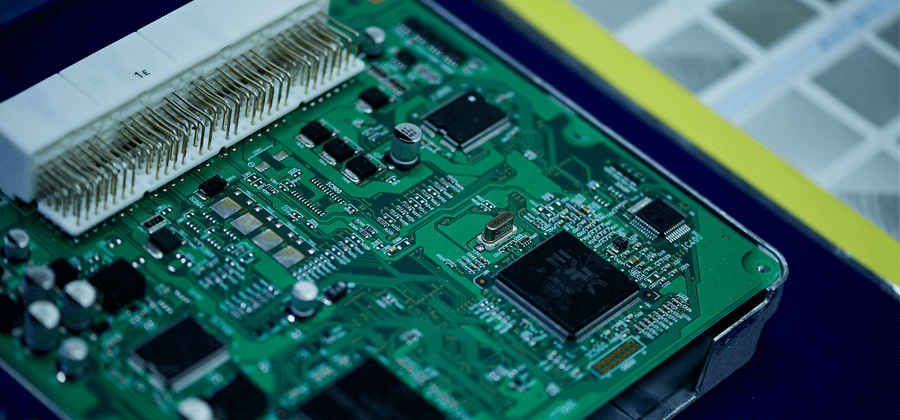

Processes developed to satisfy customer requests

Nishihara Ricoh possess many excellent technologies. They say that their greatest strength is the capability to provide solutions by making use of the technology they have cultivated for many years as well as their human power. Engineers directly communicate with customers and propose solutions to avoid potential issues in all processes from product planning and development to trial manufacturing and mass production. "At first the sales staff work as a bridge," President Nishihara explained. "After we establish relationships of trust with our customers, our engineers move on with the customer’s engineers. Our engineers can find problems immediately or discover new hidden issues by talking directly with the customer. We sometimes develop a device independently to satisfy customer requests. We promote projects in this way without making customers worry. We call this Process Support Engineering (PSE), and we have been using it to provide value to our customers."

With PSE, Listening to Customers, Accepting their Ideas, and Advancing Development Together

President Nishihara talking about PSE

"Some time ago, we received a capacitor plating request from a customer," President Nishihara told us. "The initial problem was that when they tried to solder a part smaller than a grain of rice on a board, its position changed slightly with the melting of the solder. Gas emitted from the solder on melting displaced the part from its specified position. Since we were asked to solve this problem, we had been developing plating that melts well without emitting gas. During development, the customer consulted us about user complaints regarding plating discoloration. So, we also developed plating capable of solving that problem. This pleased the customer very much. We should listen to customers, clarify problems, and proceed with development together. I think this is how we can satisfy customers and gain their trust."

TPM Activities Greatly Improve Productivity

Well-managed, dust-free factory

Nishihara Ricoh is working on PSE, but they have also focused on Total Protective Maintenance (TPM) activities since 2004 to raise production efficiency by making various improvements. "We launched our TPM activities because our factory failed in certification by a semiconductor-related customer," President Nishihara told us. "We thought we had been doing well, but the customer seemed to think that our management was insufficient for a factory handling semiconductor-related products. We thought we had to do something about it, and started working on TPM at once." Machine faults subsequently decreased about 60%, the yield rate improved remarkably, and productivity was nearly tripled. In acknowledgment of these activities, the Japan Institute of Plant Maintenance awarded the company the TPM Excellence Prize in 2017. "We will continue with TPM. It is very good that we have been working on TPM," said President Nishihara. He was impressed with its effects.

Considering Proactive Use of J-GoodTech to Ascertain Society’s Needs

Nishihara Ricoh has continued to challenge themselves to various activities as a plating company. For example, they acquired ISO 9002 certification for systematic quality management. They were early to start applying lead-free plating to mass production to comply with regulations regarding lead, and acquired a joint patent about measures against whiskers.* They say that the past experiences of President Nishihara are the foundation of these proactive activities. "I have experienced how business cycles have a significant impact," said President Nishihara."Considering my experience, I think we should continue to promote our company and develop technology even when work decreases due to a bad economy. That will have a great effect on later business." He said he would expand their perspective to something new. "We have been making proposals and having sales negotiations through J-GoodTech to satisfy needs from major companies, but we will use J-GoodTech even more.There are extensive variations in plating depending on the materials, specifications, and characteristics. We want to collect information through J-GoodTech about what customers are expecting as well as society’s needs. We want major companies to have extensive knowledge about our technologies," President Nishihara said about his plans for the future.

*This is a phenomenon of needle-shaped or nodule-shaped metallic single crystals growing on a metal surface. Whiskers between electronic circuits may cause a short circuit.

FROM J-GoodTech

The corporate philosophy of NISHIHARA RIKOH Co., Ltd. is to provide reliable technology and sincerity. The company has been applying this philosophy in plating semiconductor and electronic parts with their high technical capabilities, excellent quality management system, and skills capable of satisfying customer needs. They are making use of J-GoodTech as a means of learning about the technology expected by customers as well as society’s needs.

J-GoodTech is a business matching site where you can obtain information about technologies, products, and services of various companies. You can post technical terms leading to the introduction of your company and widely disseminate information through the website. The website also has needs communication function where major companies and SMEs can spread information about needs. Companies like NISHIHARA RIKOH Co., Ltd. trying to confirm society’s needs are also using the website. We hope you will make the most of J-GoodTech.

Related Links

Takanawa Co., Ltd.

Takanawa Co., Ltd, High Precision Thin Parts Specialist, Has Plant In Fukushima & Thailand.

Showa Precision Tools Co., Ltd.

How Showa Precision Tools Co., Ltd has expanded its business to the global market and stays competitive.

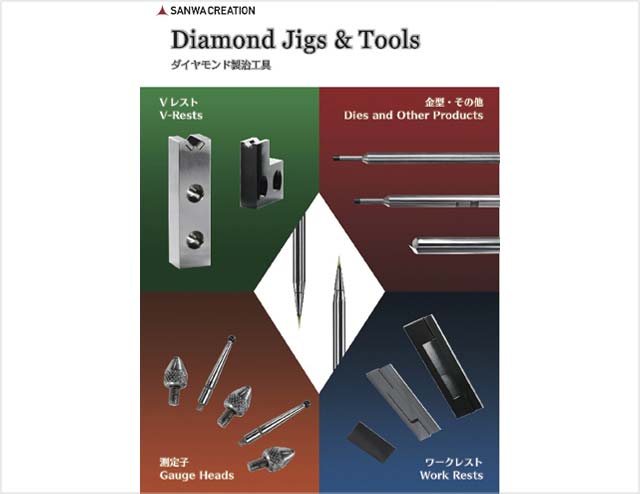

Sanwa Creation Co., Ltd.

Sanwa Creation, a J-GoodTech registered company, has been a manufacturer and distributor of high precision pins and shafts since it is founded in 1999.

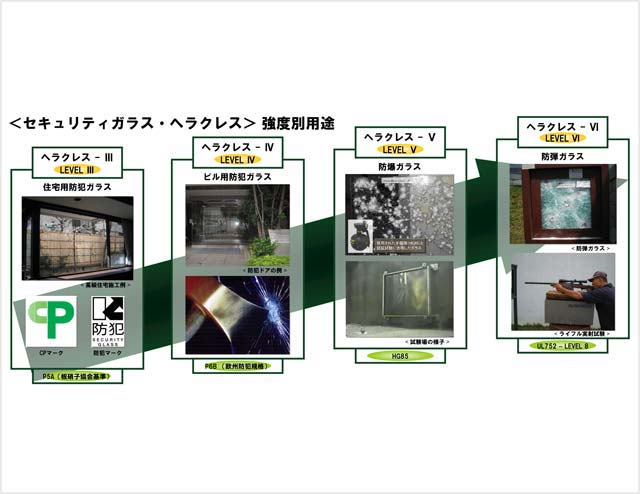

Hercules Glass Tech Co., Ltd.

Hercules Glass Tech, a J-GoodTech registered company, is an advanced glass manufacturer with an innovative technology for glass production.

Shin Tokyo Engineering Co., Ltd.

Shin Tokyo Engineering, a J-GoodTech registered company, has technical expertise on producing crimping tools and pressure-welding tools.

Kanepackage Co., Ltd.

Kanepackage Co., Ltd.

Aiming to extend the use of high-quality packaging materials around the world

KOJIMA GIKEN KOGYO Co.,Ltd

A Global Niche Top Manufacturer of Skewering Machines Grown by Continuing Efforts to Satisfy User Requests

NISHIHARA RIKOH Co., Ltd.

Thorough Quality Management and Various Other Actions to Establish Relationships of Trust with Customers

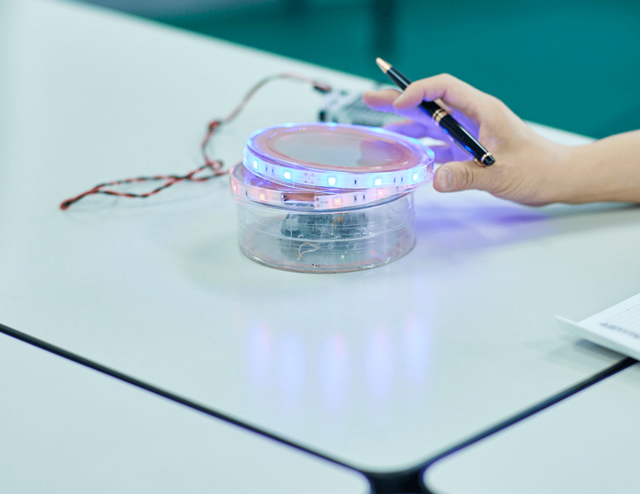

B & PLUS K.K.

Wanting to be a Manufacturer Developing the Limitless Potential of Wireless Power Supplies

TENHIKO INDUSTRIAL CO.,LTD (First Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (First Part)

TENHIKO INDUSTRIAL CO.,LTD (Second Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (Second Part)