Client Stories

Kanepackage Co., Ltd.

Aiming to extend the use of high-quality packaging materials around the world

Ryoichi Kanesaka, President, Kanepackage Co., Ltd.

Photo of the company’s staff in front of the main entrance

ABOUT THE COMPANY

Kanepackage Co., Ltd. was founded in 1976, and has been designing and developing packaging materials that play a key role in physical distribution for more than 40 years. In 1996, 20 years after its foundation, the company marked a turning point. They established a plant in the Philippines, and made their first advance into an overseas market. With this plant as a foothold, the company has expanded its business into China, Vietnam, Thailand, Indonesia, and Mexico. Why did this company try to expand its business not only in the domestic Japanese market, but also into overseas markets? What were they thinking at the time? We interviewed Ryoichi Kanesaka, the company president.

Training human resources in the Philippines, and advancing into a series of overseas markets

The Philippine plant as a foothold for expanding business into overseas markets

“In 1996, one of our customers decided to establish a plant in the Philippines and reduce production in Japan,” President Kanesaka explained. “It was expected that our workload would be reduced by 20 to 30%, so we also decided to establish a plant there.” The company’s advance into overseas markets was triggered by the overseas expansion of a major home electric appliance manufacturer, which had accounted for 98% of the company’s workload. They had a lot of trouble in the early stage. However, after achieving successful results in the Philippines, they made use of the know-how they accumulated to expand their business into China, Vietnam, Thailand, Indonesia, and Mexico. President Kanesaka said they have established a system in which they train employees in the Philippines and then entrust them with business expansion into overseas markets.

Cooperating with local enterprises to provide the same quality services as in Japan

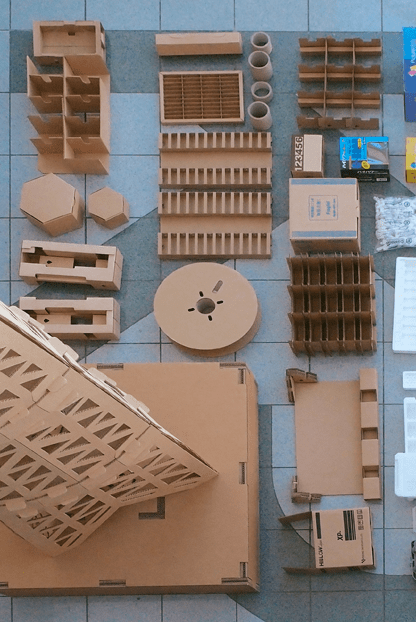

Various packaging materials provided by Kanepackage Co., Ltd.

“How to provide the same quality services as in Japan is important when advancing into overseas markets,” emphasized President Kanesaka. He told us that locally manufactured packaging materials, such as corrugated cardboard boxes, are easily affected by variations in humidity and are susceptible to printing failure. Such materials cannot satisfy the local establishments of Japanese enterprises as their customers, but procuring materials from Japan results in high costs. Therefore, it was necessary to carry out local production while conducting quality control after precisely understanding the characteristics of locally procured materials. Meanwhile, Kanepackage did not invest in equipment, but entrusted production to local affiliated factories. The company provided know-how, conducted delivery date management and quality control, gave technical guidance at each stage, and prepared a manual. In addition, the company thoroughly reinforced testing equipment. This is how they succeeded in enhancing the technical level of local staff, creating employment, and establishing a win-win relationship. In this way, the company increased its overseas bases one after another, and overseas business now accounts for 80% of the company’s sales.

New business opportunities created by believing in their own technologies and reverse thinking

Optimal packaging materials are born through various tests

Cushion design is Kanepackage’s core technology. This technology pursues how to realize compact packaging materials and protect products from impacts and accidents. Using a large amount of packaging materials increases the safety of the products, but material costs and large boxes are required, which results in high physical distribution costs. Using a large amount of packaging material may be profitable for the company, but President Kanesaka reversed this thinking 20 or more years ago. “How can I make packages compact to reduce costs and save resources? We possess excellent technologies, so why don’t we promote them to our customers?” They pursued the smallest, lightest package that can protect a product, and acquired a patent. This was how they could acquire new customers they had never done business with before. “With regard to cushion design, we believe that our technology ranks among the top in Japan,” he said proudly.

Design and development capabilities polished by understanding the customer’s products

This protector can protect a raw egg even if it is dropped from a height of 200 meters.

“There is another thing we emphasize, and that is to understand the customer’s products very well,” President Kanesaka continued to explain. “There are many products where the center of gravity is not at the center of the main body. If such a product is dropped from somewhere during transportation, what part of the product receives the strongest impact? If we do not understand the structure of the subject product or the materials used to make it, we don’t know what kind of packaging materials should be used or where they should be used, so we cannot protect the product.” Such consideration for products sometimes leads to receiving an order for a special packaging material. He said that they were entrusted with developing a packaging material used to transport a globally unique piece of observation equipment that was to be incorporated in an artificial satellite. “It’s just packaging materials, or so you might think,” he said. “But they involve various kinds of sophisticated know-how, which makes our work difficult, but interesting.”

Targeting the North American market with the know-how they have cultivated

We asked Mr. Kanesaka about their future prospects. “We want to advance into the US market in the near future,” he replied. The company advanced into Mexico in 2017, and manufactures packaging materials for automotive parts exported mainly to the US. “A lot of parts are imported from the US, but their packaging materials are poor in quality and sometimes involved accidents,” he said. “So, we determined to advance into the US, since we understood the circumstances of our customers while operating in Mexico.” President Kanesaka cherished the idea of spreading packaging materials for safe and secure transportation in the North American market. He also wants to continue spreading high-quality packaging materials not only in the domestic Japanese market, but also overseas markets, including those where the company has already advanced. “This is why we want to strongly promote our design and development capabilities via J-GoodTech and so on,” he continued. “We possess testing equipment equivalent to those of testing and evaluation institutions. We reproduce a transport environment close to the actual one to conduct drop, vibration, and compression tests, and we use this to improve the quality of our products. This is how we have gained the trust of our customers. We want to further expand our business.” We could understand President Kanesaka’s strong will to further spread compact and resource-saving but high-quality packaging materials around the world.

FROM J-GoodTech

Based on their unique management system and established technologies, Kanepackage Co., Ltd. is expanding its business into overseas markets one after another. The company is continuing its ambitious activities to acquire new customers. They actively participate in business meetings with overseas enterprises, which are held by J-GoodTech, to advance negotiations.

J-GoodTech emphasizes business matching with overseas enterprises, and particularly Southeast Asian enterprises, via the website. J-GoodTech’s coordinators are familiar with the various regions and provide support in business meetings. Information on various technologies, products, and services can be obtained without a cost burden, so J-GoodTech is utilized by many enterprises that intend to actively expand their business into overseas markets, like Kanepackage. We hope you will make use of J-GoodTech, and you are sure to have opportunities for business matching with enterprises that you have not encountered before.

Related Links

Takanawa Co., Ltd.

Takanawa Co., Ltd, High Precision Thin Parts Specialist, Has Plant In Fukushima & Thailand.

Showa Precision Tools Co., Ltd.

How Showa Precision Tools Co., Ltd has expanded its business to the global market and stays competitive.

Sanwa Creation Co., Ltd.

Sanwa Creation, a J-GoodTech registered company, has been a manufacturer and distributor of high precision pins and shafts since it is founded in 1999.

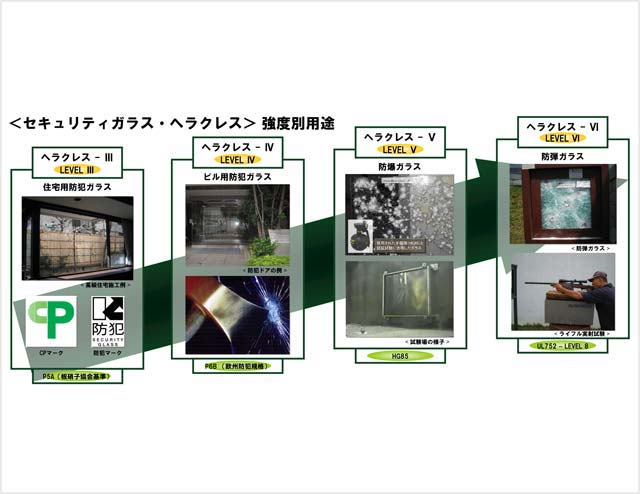

Hercules Glass Tech Co., Ltd.

Hercules Glass Tech, a J-GoodTech registered company, is an advanced glass manufacturer with an innovative technology for glass production.

Shin Tokyo Engineering Co., Ltd.

Shin Tokyo Engineering, a J-GoodTech registered company, has technical expertise on producing crimping tools and pressure-welding tools.

Kanepackage Co., Ltd.

Kanepackage Co., Ltd.

Aiming to extend the use of high-quality packaging materials around the world

KOJIMA GIKEN KOGYO Co.,Ltd

A Global Niche Top Manufacturer of Skewering Machines Grown by Continuing Efforts to Satisfy User Requests

NISHIHARA RIKOH Co., Ltd.

Thorough Quality Management and Various Other Actions to Establish Relationships of Trust with Customers

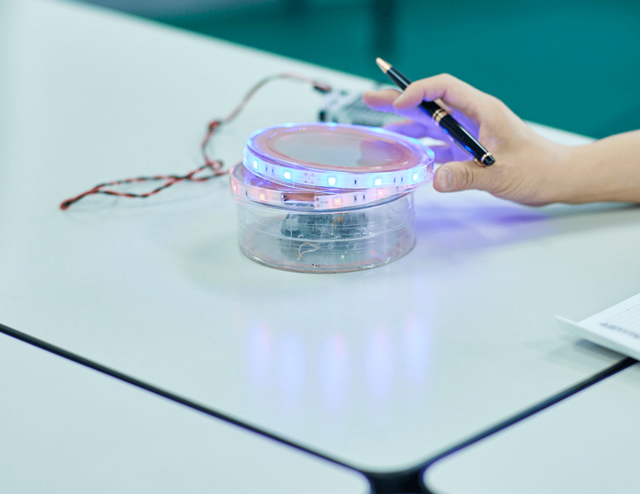

B & PLUS K.K.

Wanting to be a Manufacturer Developing the Limitless Potential of Wireless Power Supplies

TENHIKO INDUSTRIAL CO.,LTD (First Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (First Part)

TENHIKO INDUSTRIAL CO.,LTD (Second Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (Second Part)