Client Stories

A Global Niche Top Manufacturer of Skewering Machines Grown by Continuing Efforts to Satisfy User Requests

Michihiro Kojima, Representative Director and President, KOJIMA GIKEN KOGYO Co.,Ltd

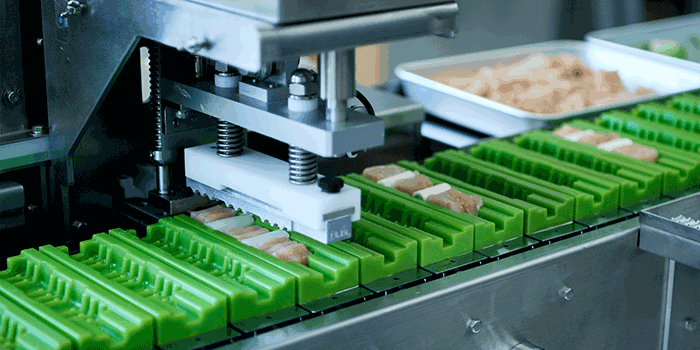

Photos of skewering machine trays of various shapes

ABOUT THE COMPANY

KOJIMA GIKEN KOGYO Co.,Ltd has been researching skewering machines and satisfying user requests by trial and error since its establishment in 1981. The company started its history against a headwind because the skewering machines made by previous manufacturers were unpopular and had instilled a negative image in people. However, the company gradually gained trust and grew enough to receive many orders and inquiries, in Japan and abroad. How did the company change the past image of skewering machines and gain trust? What are they aiming for? We interviewed Mr. Michihiro Kojima, Representative Director and President.

Modestly Getting the Hang of Manual Skewering and Renewing the Image of Skewering Machines

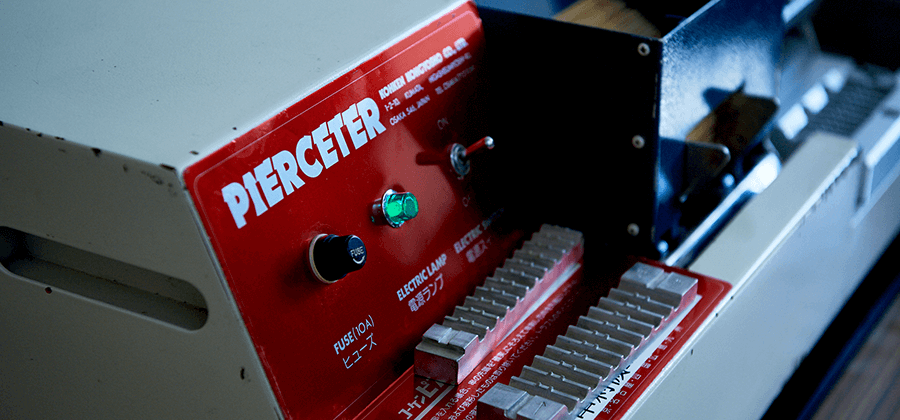

A skewering machine manufactured at the beginning of the company’s establishment that still works to this day

"At first, we were almost always turned away at the gate by people saying skewering machines were useless," President Kojima recalled, about the situation when the company was established. There were more than 20 manufacturers of skewering machines at the time, but the machines had low reliability and people had a bad image of them. "We asked yakitori and meat shops to let us go in and see their skewering work. We got the hang of manual skewering and reproduced it mechanically. This is why our machines were different from the others." They applied this confidence in nationwide sales activities, and their machines began to sell little by little. This is how the skewering machines of Kojima Giken Kogyo gradually become popular in the industry.

Sincerely Considering Customer Feedback as the Basis of Product Development

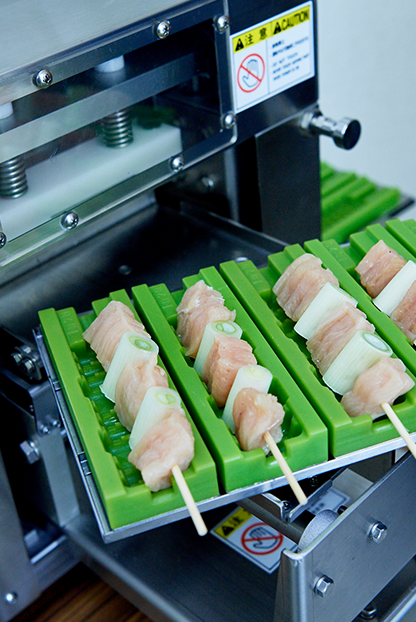

Mechanically reproducing the skills of manual skewering

When their machines gradually started selling, Kojima Giken Kogyo received a development request from a major manufacturer of electric machines for skewers on frankfurter production lines. This successful development made the company even more widely known. The company continued to receive orders, including one for large yakitori skewering machines from a major food manufacturer and one for oden skewering machines from a major convenience store chain. "We attach importance to what customers are expecting and are always thinking of realizing their expectations," President Kojima told us. "This is our company's policy. When we started our business, we visited many customers and asked them why they were not satisfied with the skewering machines of other manufacturers. We found out about their problems, observed manual skewering, and got the hang of a number of things, and successfully created a machine that satisfied customers. We have maintained the same approach ever since. We listen to customer ideas and solve problems one by one to give shape to these ideas. We have been building up our technology by satisfying customer requests. I think this is why our company is now successful."

It Is Not Easy to Copy Technology Built Up for Over 35 Years

Various trays for ingredients manufactured to satisfy customer requests

The company receives various requests from customers. For oden skewering machines, for example, customers requested that the ingredients should not come off easily. They also made many difficult-to-satisfy requests. They wanted skewers to stop at the tips of ingredients without piercing through them so that the styrene foam containers for oden would not be damaged at shops. They also wanted not only round skewers, but also square skewers and skewers with an irregular shape called Teppo skewers. The company continued to make improvements by satisfying these requests. This is how the machines continued to evolve and be improved. At the time, the speed of evolution was too fast for them to create brochures, because the information about the machine soon became out of date. It is not easy to copy the technology they have built up for over 35 years since the company was established. Some companies manufactured and marketed similar machines by copying the technology, but did not last long. They withdrew from the business before people knew it.

Globally Broadcasting Videos Leads to Inquiries from Around the World

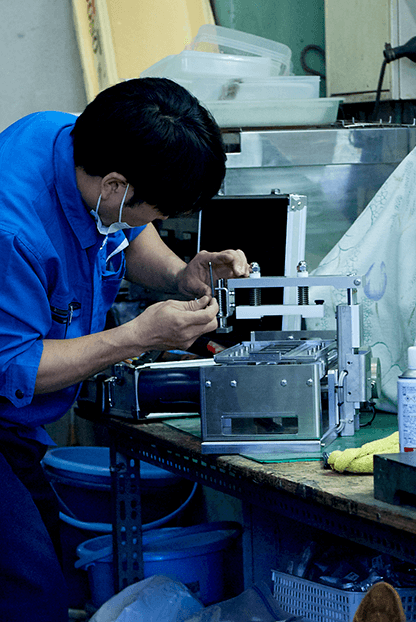

Machines carefully manufactured one by one for improved durability

"As the Internet caught on, we created a website and succeeded in increasing the number of orders from overseas," President Kojima said. "Now many people contact us after viewing our YouTube videos. At first, many orders were for machines skewering local foods, such as barbecue in the United States and satay in Southeast Asia. Since Japanese foods have become popular, 80% of our sales are now skewering machines for yakitori. We receive many orders particularly from Europe." One of the reasons for their overseas success is that the machines do not readily break. The mechanical strength against motor output is doubled and the frames are manually welded one by one to ensure durability from the basic design stage. In addition, their large machines have computer diagnosis functions to enable troubleshooting by phone or email. The company has less than twenty employees, but they sell machines in Japan and abroad without any difficulty. This is because they have greatly reduced the trouble of visiting customers for repairs. Indeed, because their machines can be used for as long as 20 to 30 years, it seems the problem is the low demand for replacements.

The Need for a Partner Company to Boost Manufacturing Capacity

"We still receive one or two inquiries a day within Japan and three or four inquiries a week from overseas because our videos about skewering machines are released on the Internet," President Kojima continued. "However, there are still many companies and shops that do not know about our products. We feel that our demand cultivation efforts are still not enough. We want to expand our markets more and more, but we have a problem of production not keeping up. The subcontractors around our company are not enough for machine production." The company wants to find partner companies for part manufacturing and maintaining machines throughout Japan. They are also considering the implementation of robotics technology to upgrade machines. "We want to promote robotization because it seems that labor shortages will become serious in the near future. However, it is still difficult to handle food and water with current robotics technology. I feel that university laboratories and SME startups have more potential regarding such technology than major robotics manufacturers. It will be good if we can find such partners," President Kojima said, about his view of the future.

FROM J-GoodTech

KOJIMA GIKEN KOGYO Co.,Ltd has been building up unique technology for many years as a global niche top company manufacturing skewering machines. They have acquired many orders in Japan and abroad by starting Web marketing, such as website production and video distribution. The company registered with J-GoodTech to look for partner companies who can help with machine manufacturing.

J-GoodTech is a business matching site where you can obtain information about technologies, products, and services of various companies. Many companies like KOJIMA GIKEN KOGYO Co.,Ltd who are looking for partner companies are using the website. You can gain opportunities for business matching with companies that you could have never have met before. We hope you will make the most of J-GoodTech.

Related Links

Takanawa Co., Ltd.

Takanawa Co., Ltd, High Precision Thin Parts Specialist, Has Plant In Fukushima & Thailand.

Showa Precision Tools Co., Ltd.

How Showa Precision Tools Co., Ltd has expanded its business to the global market and stays competitive.

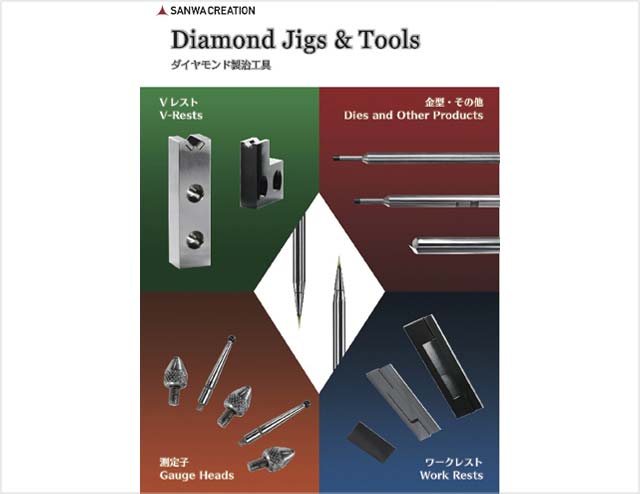

Sanwa Creation Co., Ltd.

Sanwa Creation, a J-GoodTech registered company, has been a manufacturer and distributor of high precision pins and shafts since it is founded in 1999.

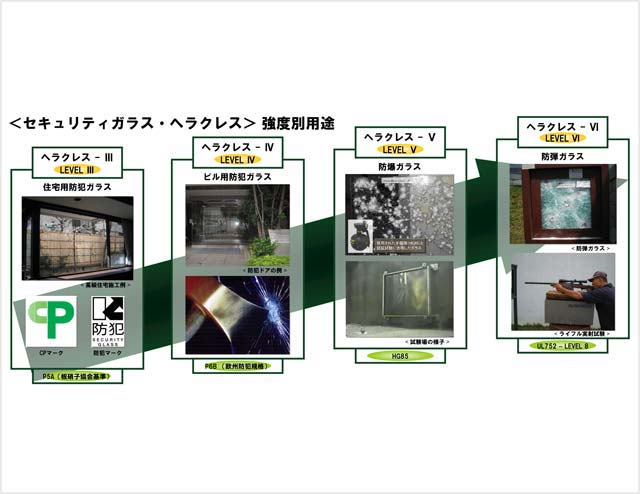

Hercules Glass Tech Co., Ltd.

Hercules Glass Tech, a J-GoodTech registered company, is an advanced glass manufacturer with an innovative technology for glass production.

Shin Tokyo Engineering Co., Ltd.

Shin Tokyo Engineering, a J-GoodTech registered company, has technical expertise on producing crimping tools and pressure-welding tools.

Kanepackage Co., Ltd.

Kanepackage Co., Ltd.

Aiming to extend the use of high-quality packaging materials around the world

KOJIMA GIKEN KOGYO Co.,Ltd

A Global Niche Top Manufacturer of Skewering Machines Grown by Continuing Efforts to Satisfy User Requests

NISHIHARA RIKOH Co., Ltd.

Thorough Quality Management and Various Other Actions to Establish Relationships of Trust with Customers

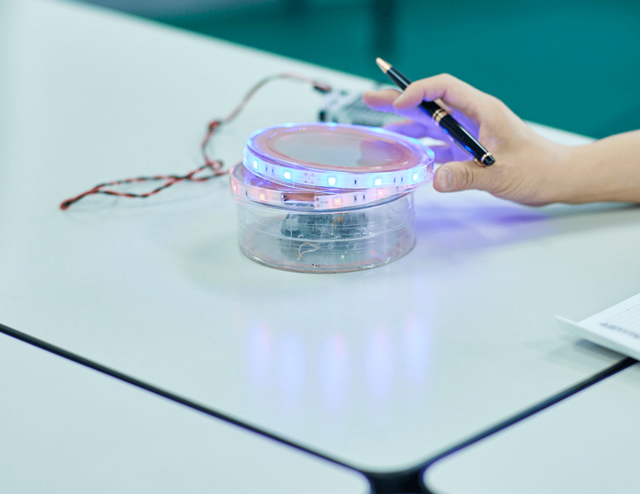

B & PLUS K.K.

Wanting to be a Manufacturer Developing the Limitless Potential of Wireless Power Supplies

TENHIKO INDUSTRIAL CO.,LTD (First Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (First Part)

TENHIKO INDUSTRIAL CO.,LTD (Second Part)

Business Strategy of Tenhiko Industrial Aiming to be the Most Rewarding Company in Japan (Second Part)