Highlights

Contributing to a Remote "Connected - Communicative Worksite" Through Wearable Computer Glass / WESTUNITIS Co., Ltd.

Thinking About the Digital Transformation of SMEs During and Post COVID-19 Era

WESTUNITIS Co., Ltd. (headquartered in Osaka City) develops and manufactures both wearable computers in the form of glasses and software to support work, helping to improve the efficiency of manufacturing, construction, logistics and other workplaces.

With the digitalization of remote operations and records, which are expected to increase more and more in the future, the company contributes to the acceleration of DX (Digital Transformation) of SMEs.

In-house Planning and Development of Both Smart Glass and Software

"Here is our company's wearable computer glass, or so-called smart glass. I think you remember when Google Glass was talked about quite a bit, but that is a BtoC product, and this is a product that specializes in BtoB."

That is how Hidetaka Koya described the InfoLinker3, a new product launching in Spring 2021. He is both the sales team leader and a worksite issue consultant, in addition to holding a national qualification as a professional engineer (Industrial Engineering).

Hands-free, with the ability to switch between all display screens.

Image of the InfoLinker3 in use (healthcare).

The neckbands and head mounts that are in the smart glass that this company makes are filled with a variety of things, such as a small display that shows text and video, a camera, an inner mic, speaker, bone-conduction earphones, etc. Also, by adding the world's first LTE module, it is designed to be able to have comfortable transmissions from any place.

Not just sticking to hardware, by also planning and developing their own linking worksite support software "LinkerWorks", being able to offer one-stop services is this company's biggest strength. They have separate teams within the company that specialize in hardware and software, and work together simultaneously in development.

"There are a number of manufacturers abroad that are making BtoB smart glass, but there are many cases where they have to work with applications from other companies in order to be able to handle the job on-site. Since our company offers both hardware and software, you can use them right away on-site, and we can follow up as well. I don't think there are any other companies like this in the world," said CPO and head of software development Kazuhide Kito, giving us a glimpse of his confidence.

Wearable Computer Glass, the InfoLinker3

Improving Work Efficiency Through Remote Technological Guidance and Automatic Recording

Two of the major solutions that this company's products offer are "Remote Work Support" and "Work Navigation"

A worker and director are constantly connected through a network, and can share their work with one another.

Left: A worker wearing the InfoLinker3. Right: A director observing LinkerWorks screen.

In "Remote Work Support", the worker on-site wears a smart glass, and connects with the director in a separate location through a network. While watching the live-feed sent to his/her PC, the director can offer guidance and support in real time by sending and receiving sound or text, sharing their PC screens, marking images, etc.

In "Work Navigation", they can create step-by-step instructions in the software beforehand, and the worker can see those steps as they follow instructions performing the work. Here too, the director can monitor the progress of the work from a separate location.

"By standardizing so that even a newcomer can follow the techniques of a veteran worker and do the work, we have been able to contribute to improvements in work efficiency, and increased quality and production. In addition, by filming and photographing the process, work reports that had always been written by hand can be created automatically, so it is contributing to the digital transformation of office work as well," Mr. Koya said.

Since the distance between the worker wearing a smart glass and the director operating the software makes no difference, it is expected that this strength will be used even more during and post COVID-19 era, or in communicating with worksites outside Japan that are difficult to visit.

"And as a third solution, we are thinking about developing a "work analyzer" that stores, analyzes, and makes use of data, to help constantly improve different issues," Mr. Koya said.

A History That Began as a Work Manual Production Company

In the background of this company that plans and develops both their own hardware and software is a unique history that accumulated over time.

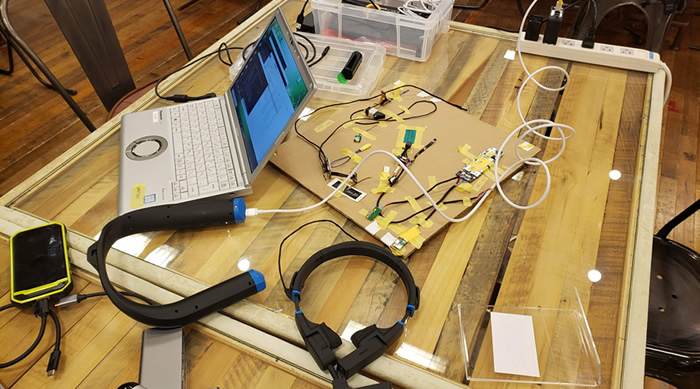

Software is being developed in two locations, Tokyo and Osaka.

"Our company began in 1984 and was initially established as a work manual production company. However, paper manuals have demerits such as being heavy, difficult to read, and hard to use if you're wearing gloves on-site, etc., so we progressed toward creating animated video manuals that are intuitively easy to understand," Mr. Koya said.

However, you can't take a PC display to the worksite to watch a video. "So that's why in 2001, we began developing wearable computer software, so that workers can see the manual while they do their work."

For a long time, they had wearable computers that were available on the market customized for worksites, and in 2014, they began developing and selling their own wearable computer. In 2015, they unveiled the "InfoLinker", a small computer terminal with a single eye head mount attached that made hands-free work possible.

From then, there were even more cases where it was used in production, construction, and distribution, and in recent years, they have expanded from their conventional industrial uses into the medical field and are finding even more uses for it.

We Want Smart Glass to be Used in Even More Industries

"What's most important for us is how much value can we provide for the client's work. Even now, we talk with people on-site and tenaciously continue to find ways to improve. For example, when we heard that the worker didn't understand how to operate the smart glass, we made it so the director at the PC could operate it remotely. This was a specific functional request from a customer that we incorporated into the product," Mr. Koya said.

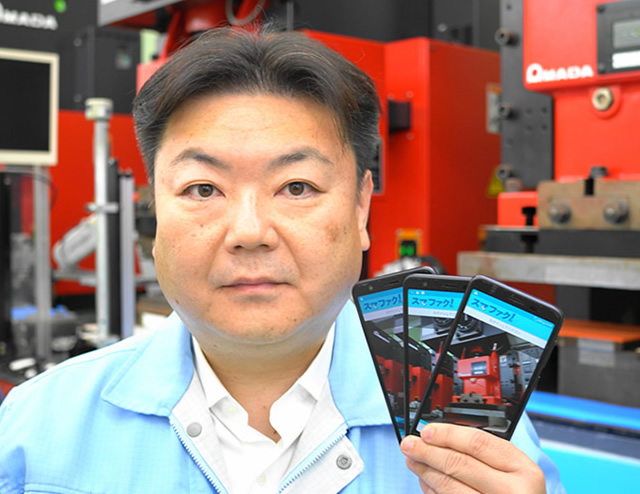

A scene from the development of InfoLinker3

In addition, with requests such as "an alert for worker heat exhaustion", "a camera that can zoom and film while showing the size of something", etc., the development team continues to look into these requests one at a time.

In order to listen to the clients and improve their product even more, it needs to be used in a variety of fields. "There are still so many more purposes and fields where smart glass can be used that even us developers don't know yet," both Mr. Kito and Mr. Koya said.

"We are now able to put the SIM of a LTE in the InfoLinker3, but when we enter the 5G era, we should be able to have an even larger amount of data go back and forth at a high speed. That will open up even greater possibilities, so I want to develop more new functions," Mr. Kito said.

As long as it is connected to a network, the smart glass and specialized software allows back and forth communication of the status of the worksite and data, regardless of distance. Perhaps we can say that scenes where these can be used to speed up the digital transformation are still, still so infinite.

FROM J-GoodTech

Smart glass and specialized software. Initial reaction was that it would be difficult to operate, but just like a smart phone, you can operate it intuitively without looking at a user's guide. That makes sense, something that can only be expected from a company that originally made manuals for complicated work processes!

Since smart glass are wearable like glasses and can be operated via voice command, it is hands-free for the worker and improves safety.

With the right idea, it can be expected that the technology would lend its strength to the digital transformation of a variety of industries.

In the future, J-GoodTech will continue to focus on SMEs that own such technology and outstanding services, and promote activities that will bring them to the attention of more companies.

Related Links

Contributing to Daily Record Automation with a Daily Report App using QR Codes / Sanko-Giken Corporation....

Making Touch-less Operation a Reality with Reasonably Priced Micro Gesture Sensors / A-Sum Technology, LLC....

Contributing to a Remote "Connected - Communicative Worksite" Through Wearable Computer Glass / WESTUNITIS Co., Ltd....

With a small drone and image analysis technology, Liberaware Co. Ltd. has made the work of inspecting narrow, dark, and dangerous places more efficient....

Thoughts on the Digital Transformation of SMEs during and post COVID-19 Era

It has long been said that the future is unpredictable in our world, but the 2020 outbreak of COVID-19...

The Contour of SME Management Required in the New Era

Open Innovation for Regaining SME Power in Japan(5th Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

Open Innovation with Large Companies

Open Innovation for Regaining SME Power in Japan(4th Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

The Role of Technological Partner within an Ecosystem

Open Innovation for Regaining SME Power in Japan(3rd Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

New Business Development with Open Innovation

Open Innovation for Regaining SME Power in Japan(2nd Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

Open innovation = Redefining Client Relations

Open Innovation for Regaining SME Power in Japan(1st Article)/Prof. Kazuyuki Motohashi, The University of Tokyo