Highlights

With a small drone and image analysis technology, Liberaware Co. Ltd. has made the work of inspecting narrow, dark, and dangerous places more efficient.

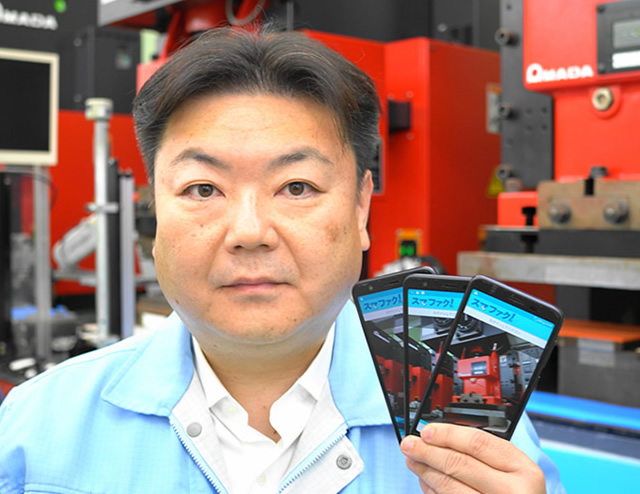

CEO Mr. Min Hongkyu holding the Liberaware's drone in his hand.

Thinking About the Digital Transformation of SMEs in the Co-existence and Post COVID-19 Era

Liberaware Co., Ltd. (Headquarters: Chiba City), founded in 2016, is developing businesses that contribute to improving productivity and safety in the manufacturing and construction industries by utilizing small specialized drones developed in-house and image analysis technology.

“With the form of service continuing to evolve, I feel a response that can contribute to the digital transformation of a variety of industries.”

Developing and Manufacturing Rare “Genuinely Japanese Made” Drones at Our Company

“We call it a drone for the narrow, dark, and dangerous places”. That was how business strategy member Yusuke Kitagawa first described the IBIS, a drone designed, developed, and manufactured by Liberaware. Everything from the frame to the battery, propellers, motor, camera, and even the flight controller “brain”, was developed by the company. I am proud to say that it is “one of the few genuinely Japanese made drones”.

The IBIS drone, designed, developed, and manufactured by Liberaware.

Liberaware’s drone is small and light. Even its longest side is less than 20 cm, and its total weight including a camera, LED light, and battery is 185 grams. The powerful dust-resistant motor developed in collaboration with Nidec Corporation, the propellers with a higher lift that are less likely to reel in dust, and the high-sensitivity camera that can take clear footage even in pitch-dark environment were the features Liberaware particularly focused on in R&D.

Company president Min Hong-kyu had been researching robotics at Chiba Institute of Technology, and started this company with a group of engineers that were his seniors and juniors in the research lab. Even with the 25 employees they have now, with the exception of the corporate department, they are almost all engineers.

Offering a ‘Straight’ Hand, From Facility Inspection to Image Analysis

There are three pillars to the company’s business. The first is inspection of the infrastructure facilities, the second is automatic patrol, and the third is image analysis and editing.

Inspecting inside of a chimney.

The first pillar, inspecting infrastructure facilities, is inspection of the inside of chimneys, pipes, and boilers, among others, and the top three companies they deal with are steel manufacturers, power companies, and oil refineries. By using a drone to inspect sites where people had taken risks in the past, such as standing on scaffolding or hanging with a rope and visually checking with a sheet of paper in hand, safety and cost performance has dramatically improved.

The second pillar, automatic patrol, brings efficiency to tasks such as checking gauge meters, server room surveillance, and managing inventory in a storeroom, etc., work that requires walking the same route many times a day. They have put a lot of work into autonomous aviation even in indoor environments that can’t be reached by GPS.

The third pillar, image analysis and editing, takes the multiple videos that were recorded during the facility inspection and makes them 3D, and develops them even more into two-dimensional imaging. This technology allows the inspector to check the images without having to watch the video from the beginning to the end and makes comparing changes throughout the years a lot easier. In the future, the company would like to create a method of AI detecting any abnormalities and determining whether any repairs are required immediately or if they should continue to observe the issue over time.

The Thought Behind a Fixed Rental Plan that Includes Cloud Services

This company’s uniqueness isn’t limited to its business, as it also extends to how it offers its services. They don’t sell the drone itself, but instead offer a fixed rate membership rental plan that includes a fee to access the cloud application for processing videos and costs for courses to learn how to operate the drone.

Inspecting inside of a silo.

“Clients fly these drones into some severe places, so they would worry thinking, ‘what would we do if we broke this drone that we just bought?’, and then they might not be able to operate the drone very well. We would like to wipe that worry away, and that’s why we offer a rental plan that is pretty much a ‘break as many as you need’ service.”

The company stated, “we want our clients to feel free to use the drone without worrying about breaking them. Since it’s a rental and all we have to do is send a new drone whenever it breaks, so they can use them without having to worry.”

Also, as a means to ease any worries that clients may have, when client companies become members they can participate in the monthly operation courses as many times as they want. These types of general courses typically cost hundreds of thousands of Japanese yen (a few thousand U.S. dollars). Companies may train one person internally to be a pilot, but that money is wasted if that person changes positions or leaves, or training many people would cost the company a lot of money as well, so these unlimited monthly operation courses are a way they came up with to help avoid these issues.

Since October 2020, they have rolled out their cloud services offering unlimited analysis and editing of images recorded by the drones, as well as 3D and two-dimensional imaging.

Aiming to Be the Company with the Most Videos of Narrow, Dark, and Dangerous Places in the World

Filming videos with drones, processing those videos (3D, point cloud, orthophotos), and automatic detection of abnormalities through AI., Mr. Kitagawa says that it is with these three steps that they can contribute to digital transformation for a wide variety of companies for the goal is “to be the company with the most videos of narrow, dark, and dangerous places in the world”.

A two-dimensional image of the inner-wall of a silo created from image processing.

“By having the most videos of narrow, dark, and dangerous places in the world, we can more accurately detect abnormalities, advise a plan for facility repairs, and we want to become a company that can help with so many more things like that.”

However, looking at the clients that this company has provided inspection services for in the past, most on the list are from heavy industries like steel manufacturers, power companies, construction companies, oil refineries, railroad companies, cement makers, garbage incineration facilities, etc. I asked Mr. Kitagawa how they would contribute to the digital transformation of a smaller company.

“The second pillar of business that we mentioned , the automatic patrol service, will be easy to implement for SMEs. For example, in March 2020, we did an experiment at the west library in Funabashi City, Chiba Prefecture, where we tried implementing an “AI Inventory Inspection System” and had our drone automatically go around and film.”

Mr. Kitagawa also mentioned the possibilities of introducing a drone into a warehouse, and having it automatically fly around at night when no one is present, collecting data and managing inventory. They can contribute to the automation, data collection, and digitalization of inspections that are currently being performed directly with a person’s eyes and writing on a sheet of paper.

The “Libera” of Liberaware means “free”. The “ware” can mean both “hardware” or “software”, and also includes being “aware”. Being aware of a problem and solving it using free thought from both a hardware and software perspective. With the services that this company creates, the future when many companies have a dramatic digital transformation is right on our doorstep.

FROM J-GoodTech

I had only ever imagined drones as something that would fly high in the sky. I was amazed by the company's idea of a "drone dedicated to narrow, dark, and dangerous places" and the technical persistence to realize it.

The "auto-patrol" function automates routine tasks such as patrols and inspections, so that extra manpower can be allocated to more creative tasks.

This can be mentioned as one of the benefits of DX.

In the future, J-GoodTech will continue to focus on SMEs that have such technological capabilities and outstanding services and promote activities that will bring them to the attention of more companies.

Related Links

Contributing to Daily Record Automation with a Daily Report App using QR Codes / Sanko-Giken Corporation....

Making Touch-less Operation a Reality with Reasonably Priced Micro Gesture Sensors / A-Sum Technology, LLC....

Contributing to a Remote "Connected - Communicative Worksite" Through Wearable Computer Glass / WESTUNITIS Co., Ltd....

With a small drone and image analysis technology, Liberaware Co. Ltd. has made the work of inspecting narrow, dark, and dangerous places more efficient....

Thoughts on the Digital Transformation of SMEs during and post COVID-19 Era

It has long been said that the future is unpredictable in our world, but the 2020 outbreak of COVID-19...

The Contour of SME Management Required in the New Era

Open Innovation for Regaining SME Power in Japan(5th Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

Open Innovation with Large Companies

Open Innovation for Regaining SME Power in Japan(4th Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

The Role of Technological Partner within an Ecosystem

Open Innovation for Regaining SME Power in Japan(3rd Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

New Business Development with Open Innovation

Open Innovation for Regaining SME Power in Japan(2nd Article)/Prof. Kazuyuki Motohashi, The University of Tokyo

Open innovation = Redefining Client Relations

Open Innovation for Regaining SME Power in Japan(1st Article)/Prof. Kazuyuki Motohashi, The University of Tokyo